- Contact Us

- -

- USD

Knowledge Center · 2025-08-05 14:39:36 · 932 hits

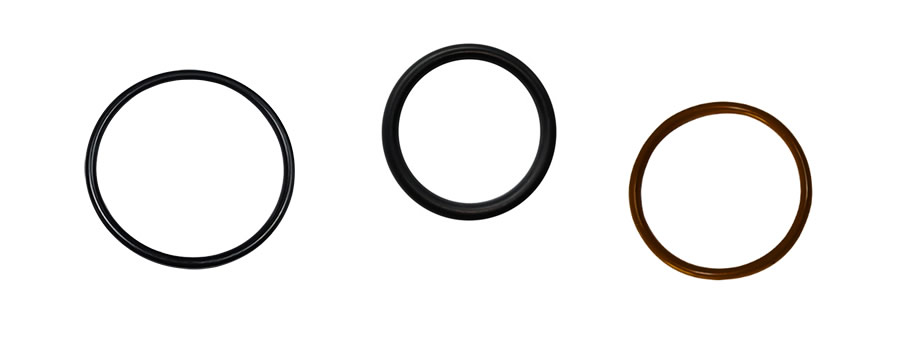

What Are O-Rings

An O-ring, like all gaskets, is designed to create a barrier between two surfaces, preventing leakage of fluids or gases.

The O-ring is placed into a groove to secure them in place, then compressed between two surfaces. When the system comes under pressure, the O-ring is squeezed against the opposite wall of the groove, maintaining a seal across a wide range of pressures. This makes them essential components in a wide array of applications, including pumps, cylinders, and connectors.

The Benefits of O-Rings

O-rings are known for their low cost, durability, and versatility. When properly maintained, they are suitable for use in a wide variety of applications, particularly in fluid power systems, such as pneumatic and hydraulic cylinders.

O-rings are ubiquitous across many industries including automotive, aerospace, and many others. Their ease of replacement and low cost provide an economical solution, allowing operators to replace the O-ring rather than the more expensive components that they are used in.

O-Rings Material Selection

O-rings are available in diverse range of materials, each suited to specific industrial applications. The material selection for O-rings depends on factors such as:

Chemical compatibility

Seal pressure

Lubrication requirements

Durometer Hardness

Size

and Cost

Common O-rings materials include:

Polyurethane

Polytetrafluoroethylene (PTFE)

Fluorocarbon (FKM)

Neoprene

Nitrile rubber (NBR)

and Silicone

The most common materials being NBR and silicone.

Nitrile Rubber

Nitrile rubber offers excellent resistance to lubricants and greases and comes at a relatively low cost.

Additionally, the chemical and physical resistance of nitrile rubber can be tailored by modifying its acrylonitrile content or altering the curing process, enabling it to meet specific application needs.

Standard grades of NBR exhibit resistance to mineral oil-based lubricants, greases, and many types of hydraulic fluids.

Silicone Rubber

Silicone rubber offers a broad temperature resistance and exceptional durability against ozone, weathering, and aging. However, compared to other elastomers, silicones tend to have less superior mechanical properties.

Despite this, they are often favored in applications where hygiene and sterile environments are of the most importance, like the food and beverage and medical industries.